Services

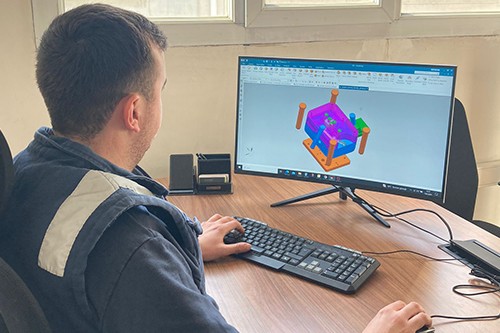

Design

Koçhan Makine is a company that provides high pressure aluminum mold and part design services to the automotive, agriculture and white goods sectors. Thanks to its expertise and experience in the sector, it offers customers solutions tailored to their specific requirements. It prioritizes customer satisfaction and product quality by strictly adhering to quality standards with innovative design and engineering solutions. Koçhan Makine is recognized in the national and international markets as a reliable business partner.

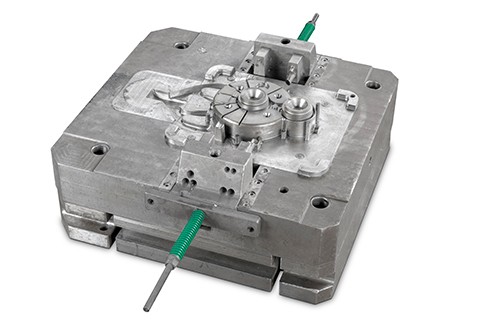

Mold Manufacturing

Koçhan Makine offers professional services to its customers in the field of high pressure mold production. Our company specializes in the shaping of metal and plastic materials in molds under high pressure for industrial needs. By offering special design and engineering solutions to our customers, we ensure the production of quality and durable parts. With high pressure mold production, we contribute to the production of complex and precise parts used in automotive, electronics, medicine, white goods and many other industries. By prioritizing customer satisfaction, we aim to be in a leading position in the industry with our innovative approaches.

Aluminum Injection

Koçhan Makine has 400 tons and 1100 tons of aluminum injection machines. These powerful injection machines are used to produce aluminum parts in accordance with industrial standards. Our company produces high-quality and durable aluminum parts used in various sectors by offering special design and engineering solutions to suit the needs of its customers. By strictly adhering to innovative technologies and quality standards, we aim to provide reliable and high-performance products to our customers. Koçhan Makina is in a leading position in the sector by prioritizing customer satisfaction with its aluminum injection machines.

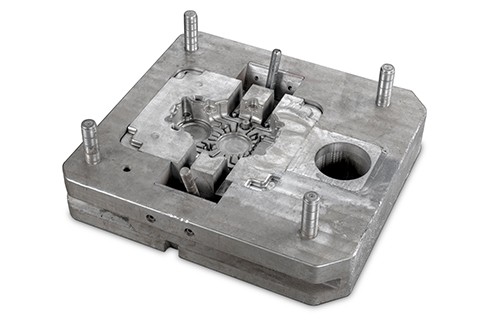

Mold Maintenance and Renovation

Üretimi tamamlanmış kalıplara yönelik tadilat ve bakım hizmetleri sunmaktayız. Firmamız, kalıpların verimliliğini artırmak, işlevselliğini korumak ve ömrünü uzatmak amacıyla özelleştirilmiş bakım ve onarım çözümleri sunmaktadır. Deneyimli teknisyenlerimiz, kalıpların detaylı analizini yaparak, gerekli onarımları gerçekleştirir ve kalıpların işlevselliğini ve performansını optimize eder. Müşteri memnuniyetini ön planda tutarak, kaliteli ve zamanında hizmet sunmayı taahhüt ediyoruz.

Quality

In order to keep quality standards at the highest level, we use Hexagon DEA and Peel 3D machines to measure the quality of the parts we produce and to design existing products by performing reverse engineering activities. Thanks to these technological opportunities, we ensure compliance with the technical drawings by making precise measurements of each part during the production phase, while at the same time we develop new designs by analyzing existing products and making use of them. In this way, we aim to maintain our leadership in the industry by constantly offering innovative and optimized solutions, as well as offering the highest quality products to our customers.