Products

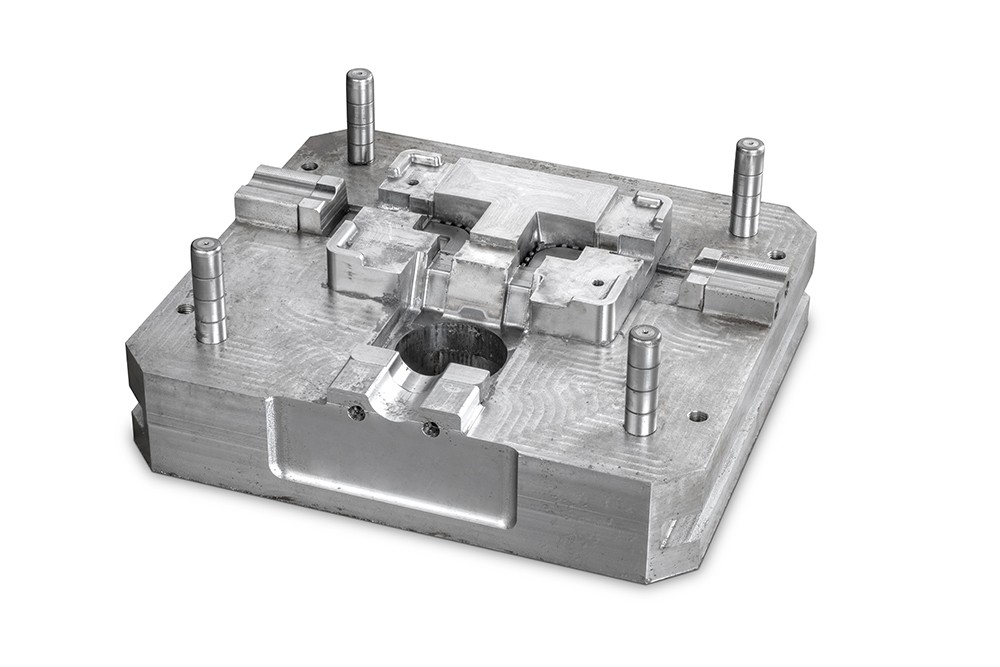

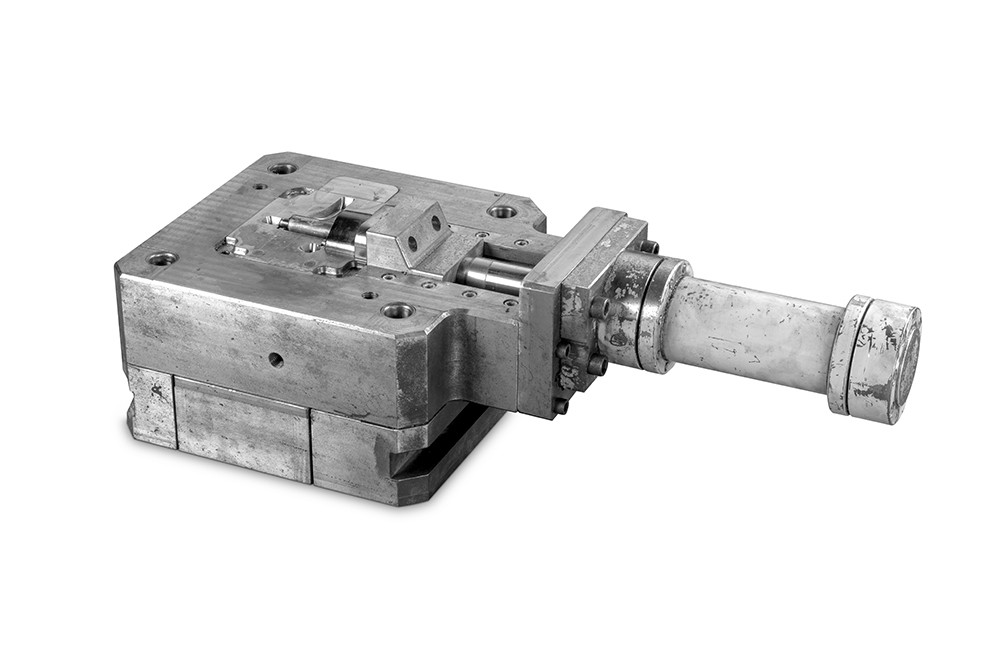

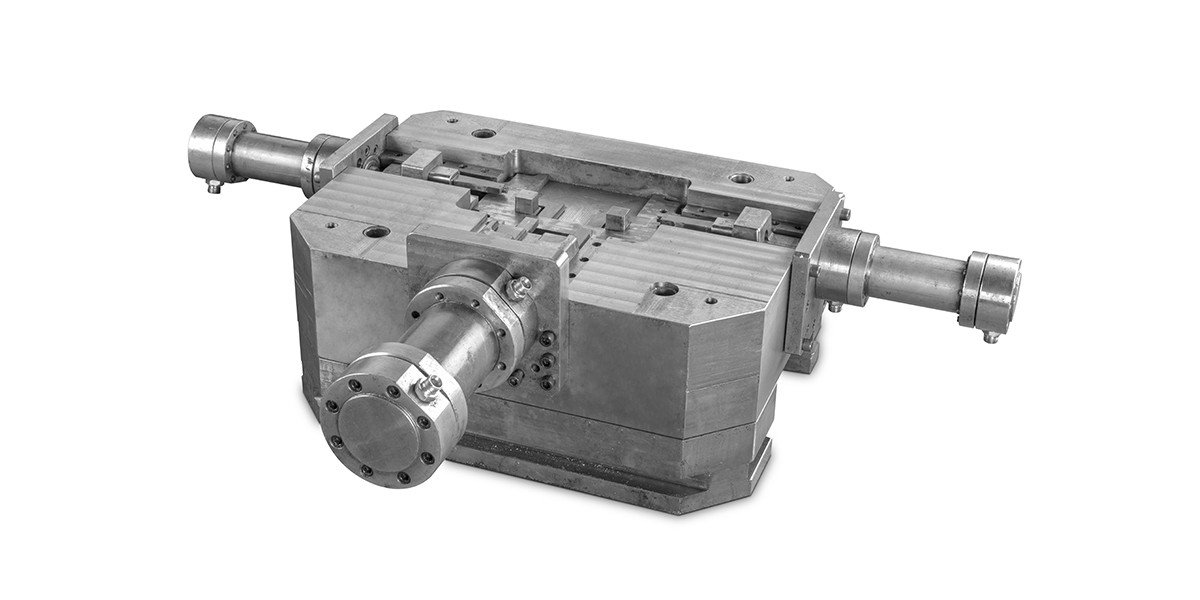

Mold manufacturing begins with determining the part and model. Then, appropriate materials are selected and permanent, aluminum and plastic molds are processed. The precision of the mold parts is ensured by using processing and measurement control apparatus. During the assembly phase, casting apparatus is produced and assembled. This process includes parts such as the machine piston, axis block and puller spindles. As a result, mold manufacturing is carefully planned and implemented, resulting in high quality and precise molds.

We produce aluminum parts with our high pressure aluminum injection machines with a capacity of 400 and 1100 tons. Thanks to this technology, we can effectively produce high-quality and durable aluminum parts that comply with industrial standards.